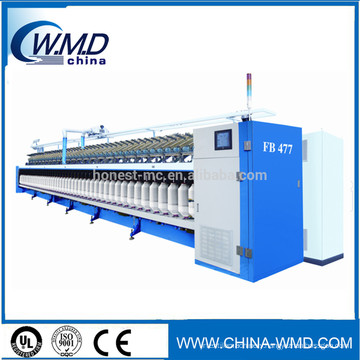

manufacture of cotton and wool spinning machine factory price

Basic Info

Model No.: FB477

Product Description

Manufacture of cotton and wool spinning machine factory price FB477 computerized wool spinning roving frame is our company based on the domestic and foreign roving machine technology,use high technology microcomputer control,a new generation of high-end computer interlligent roving equipment independently developed,with three motors to respectively drive flyer+drawing,bobbin,dragon reinforcement lifting,removal of the original three axis roving machine complex differential mechanism,main mechnical transmission system adopts the arc tooth synchronous belt transmission,realize the synchronous operation of three motors in the coordinated control of the main controller under.

Manufacture of cotton and wool spinning machine factory price FB477 computerized wool spinning roving frame is our company based on the domestic and foreign roving machine technology,use high technology microcomputer control,a new generation of high-end computer interlligent roving equipment independently developed,with three motors to respectively drive flyer+drawing,bobbin,dragon reinforcement lifting,removal of the original three axis roving machine complex differential mechanism,main mechnical transmission system adopts the arc tooth synchronous belt transmission,realize the synchronous operation of three motors in the coordinated control of the main controller under.

Manufacture of cotton and wool spinning machine factory price Characteristic 1.Remove from the original three axis roving machine complex differential mechanism,no backlash drive tension uniform,constant,maintenance convenience. 2.Having power-off protection device and constant tension spinning system,can greatly improve the evenness quality. 3.Having control system database,can ripe spining process of different varieties,different number of storage,process adjustment and convenient replacement of varieties. 4.Head driving and layout optimization design,the front layout is simple,good heat dissipation,easy installation and maintenance. 5.Optimize draft part structure,can effectively avoid the mechanical wave roller torsional vibration generated. 6.The bridge shunt type wire,electrical installation convenient,reduce electrical signal interference. 7.The main transmission adopts synchronous belt transmission,smooth transmission,low noise,high efficiency.

Manufacture of cotton and wool spinning machine factory price Characteristic 1.Remove from the original three axis roving machine complex differential mechanism,no backlash drive tension uniform,constant,maintenance convenience. 2.Having power-off protection device and constant tension spinning system,can greatly improve the evenness quality. 3.Having control system database,can ripe spining process of different varieties,different number of storage,process adjustment and convenient replacement of varieties. 4.Head driving and layout optimization design,the front layout is simple,good heat dissipation,easy installation and maintenance. 5.Optimize draft part structure,can effectively avoid the mechanical wave roller torsional vibration generated. 6.The bridge shunt type wire,electrical installation convenient,reduce electrical signal interference. 7.The main transmission adopts synchronous belt transmission,smooth transmission,low noise,high efficiency. | FB477 Main Tehnical Specification | ||

| Name | FB477 | |

| Spindle gauge(mm) | 220 | |

| Spindel number | 96,108,120,132 | |

| Package dimension(mm) | Φ150*406 | |

| Bobbin dimension(mm) | Φ45*445 | |

| Drafting system | three-roller Double/Single apron drafting system | |

| Drafting multiple | 5.1-15.6 | |

| Twist range(T/M) | 14-129 | |

| Tex)Density for yarn | Fine wool 250-714;Knitting wool 500-1200 | |

| Pressing form | YJ7-320A YJ7-320A Spring Weighting arm pressing | |

| Bottom roller diameter(mm) | Φ38,Φ32,Φ38 | |

| Top roller diameter(mm) | Φ60,Φ43,Φ60 | |

| Cleaning device | Napping roller with revoiving suction device | |

| Max Mechanical speed(R/M) | 1400 | |

| Transmission device | Three frequency inverter/servo motor | |

| Control type | Computerrized Automatic control | |

| Man-machine interaction | Touch screen | |

| Winding transmission | Gear transmission | |

| Flyer transmission | Gear transmission | |

| Winding power shaft | Universal shaft | |

| Differential device | None | |

| Reversing device | Software | |

| Yarn forming angle | Software | |

| Three auto doffing | Software | |

| Signal display | Five Lamps Indicated On Machine Headstock | |

| Tension adjustment | Software | |

| Tension fine adjustment | Software | |

| Unevenness preventing | Software | |

| Sliver faults preventing | Software | |

| Winding density adjustment | Software | |

| Twist changing | Twist Gear | |

| (mm) Can diameter | Φ400/Φ500/Φ600 | |

| (kw) Main motor power | (main motor)7.5,(Gear motor)11/7.5,(Rail motor)0.75/0.37 | |

| {db(A)} Noise standard | <85 | |

| (mm) Overall dimension(108 spindles) | 13610×3560/(4310)×2600mm | |

| (mm) Overall dimension(120 spindles) | 14960×3560/(4310)×2600mm | |

| (mm) Overall dimension(132 spindles) | 16250×3560/(4310)×2600mm | |

Contact us if you need more details on cotton spinning machine. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about wool spinning machine、spinning machine price. If these products fail to match your need, please contact us and we would like to provide relevant information.

Contact us if you need more details on cotton spinning machine. We are ready to answer your questions on packaging, logistics, certification or any Other aspects about wool spinning machine、spinning machine price. If these products fail to match your need, please contact us and we would like to provide relevant information. Product Categories : yarn spinning machine > roving frame

Other Products

Hot Products

GA736 Flexible Rapier LoomGA615F Automatic Shuttle Changing LoomGA747 Flexible Rapier LoomGA615A(1x4) Multi-shuttle-box LoomGA747B(T) Towel Rapier LoomGA615BA(1x4) Multi-arm Multi-shuttle Towel LoomGA615A4(4x4) Multi-shuttle-box LoomTextile Machinery Pirn WinderSecond 260cm Towel LoomTextile Machinery Mainly PartsTextile Machinery Part ShuttleTextile Machinery Part Dobby ControllerGA1511 Automatic Shuttle Changing LoomTappet Rapier Loom With Tuck In DeviceGA615D Auto-changing Shuttle LoomGA615K Automatic Shuttle Changing Loom